So I just installed my pinion bearings (76 front D44) everything went fairly smooth. One exception being that in my service manual it says to tighten the yoke nut to 220 pounds but if I do that the pinion is not turning, kinda stumped... I dont want to ruin what I just installed.

Announcement

Announcement Module

Collapse

No announcement yet.

pinion bearing install

Page Title Module

Move

Remove

Collapse

X

-

- Are you using a crush sleeve or a stack of pinion bearing shims to set pinion bearing preload?

- Were there shims between the pinion head and inner bearing? If so, are you starting with them to adjust pinion depth?

- Since you repalced the bearings, did you replace the races as well?

- What brand bearings did you remove? What brand bearings are you installing?

Comment

-

Im no pro and this is my first time at this.. having said that,Originally posted by jeeping1974 View Post- Are you using a crush sleeve or a stack of pinion bearing shims to set pinion bearing preload?

- Were there shims between the pinion head and inner bearing? If so, are you starting with them to adjust pinion depth?

- Since you repalced the bearings, did you replace the races as well?

- What brand bearings did you remove? What brand bearings are you installing?

1. I reused the shims that were in there.

2.no,the shims in there were stacked between the outer bearing and the

pinion shaft were it steps up in diameter as well as between the inner bearing race and diff case.

3. the races were replaced with the bearings

4. timken with timken.

Its all together now but I still have the front wheel drive unhooked (dailydriver).

I put everything back together the same way it came out,but like i said when i torq it down the pinion will not rotate..so I backed it off until it would rotate at around 25 foot pounds of torq.

I appreciate your help on this.Last edited by KillDevilBill; 10-01-2011, 02:23 AM.

Comment

-

The D44's in FSJ's in my experience do NOT use crush sleeves. They all use pre-load shims. If it does use the 2 sets of shims (one set for depth right up next to the pinion gear, and the other on the outside for pre-load) and you torque it to that, you will destroy the bearings most likely.

But doing it like you said at 25ft lbs is too much. It should be in INCH pounds, NOT FOOT pounds. If you did it in foot pounds, its way too tight and you are going to trash the bearings in a very short amount fo time.

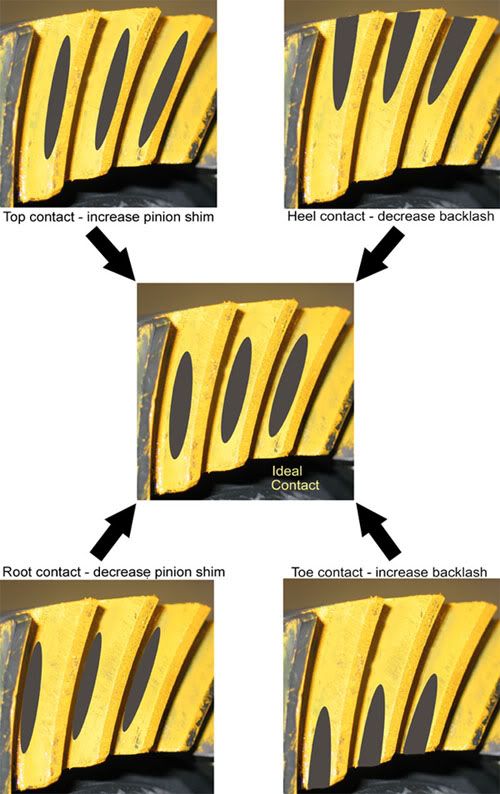

Also, if you changed out the bearings, you most likely will need to reset the gears as well. As not all bearings/races are the same. So you will need to run a patern on the mesh of the gears to be sure its right. If not, you will end up wearing them incorrectly.

Comment

-

Ok, so I havent run it yet as I have the hubs unlocked and I never really initially torqed it down that tight,,Originally posted by Stuka View PostThe D44's in FSJ's in my experience do NOT use crush sleeves. They all use pre-load shims. If it does use the 2 sets of shims (one set for depth right up next to the pinion gear, and the other on the outside for pre-load) and you torque it to that, you will destroy the bearings most likely.

But doing it like you said at 25ft lbs is too much. It should be in INCH pounds, NOT FOOT pounds. If you did it in foot pounds, its way too tight and you are going to trash the bearings in a very short amount fo time.

Also, if you changed out the bearings, you most likely will need to reset the gears as well. As not all bearings/races are the same. So you will need to run a patern on the mesh of the gears to be sure its right. If not, you will end up wearing them incorrectly.

Im just going to run the pattern and hope for the best.

Thanks for the insight

Comment

-

The pinion bearing preload rotating force should be between 14-19 inch pounds with new bearings. Make sure that your backlash is still between 0.006" and 0.010" and that your carrier cap bolts are torque to 60 foot pounds.

The pinion depth will depend on what your pattern looks like. Hopefully this picture helps some.

Comment

-

Cool.. One good thing about this setup is that you dont have to remove the inner bearing for your adjustment so being the shims are behind the inner race..and the outer comes off easily enough to get to its shims.

The only thing that threw me for a loop on this deal was the fact that it states plain as day in my 79 service manual that the torqe on the nut is 220..

That aint workin,, as I now understand this is pretty much set up like the hub/spindle bearings right?

Or is there something im not getting here?

Comment

Comment